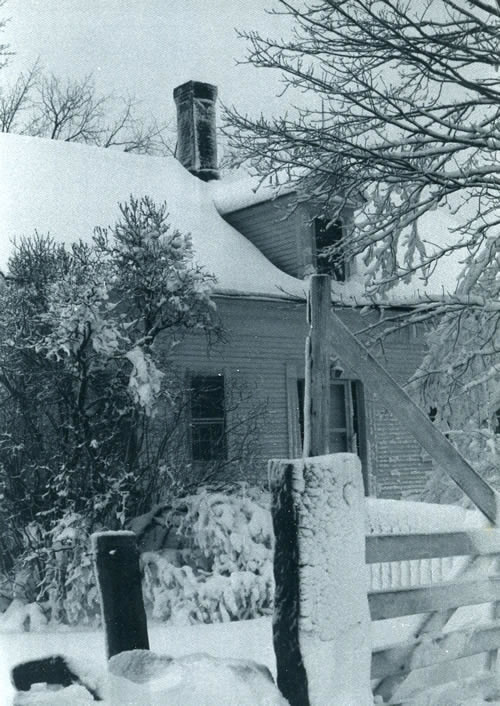

The farmhouse, barn and outbuildings looked like this when we bought it in 1971:

Winter arrived a few months after we did. We had not thought to gather or purchase firewood, and the old,

uninsulated, farmhouse was expensive to heat with an oil-fired furnace. We had a small Franklin style fireplace

in the living room and managed to buy enough wood that we could huddle about the fire with the doors closed. Much

of that winter we lived in our thermal underwear. Here's a picture of the Franklin stove in the

living room. It was a life-saver, and the only supplemental heat we had that winter.

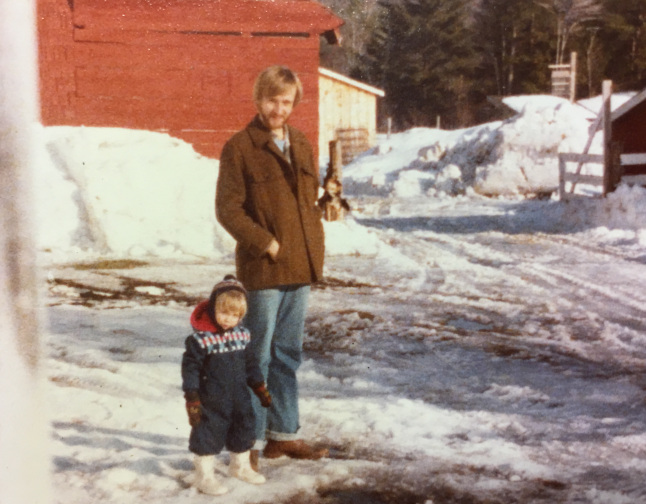

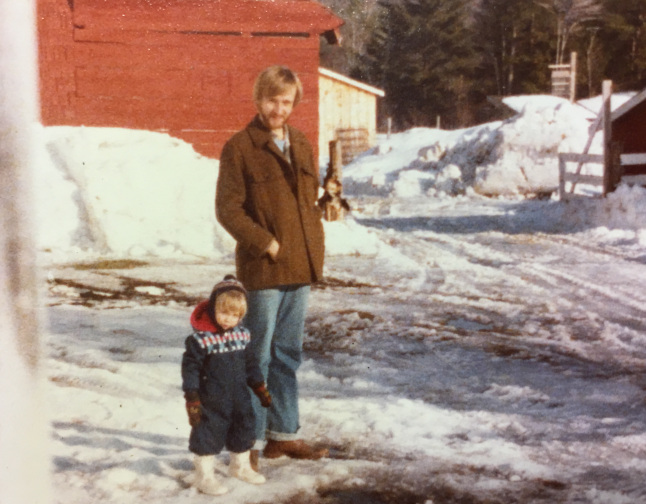

Winter looks like this in New Hampshire (pictures from 1970s and 1980s):

Brief History of our Farm - the Plummers and the town of Milton

The farm was in the "town" of Milton, which had two villlages, Milton

Mills, and the larger Milton itself. Milton had been the location of at least three ice-making operations in the

early part of the 20th century. The Salmon Falls river was dammed to form three ponds, and the town was

also known as "Milton Three Ponds". There had been railroad spurs to large wooden ice houses, one for each of the

ponds, and the main street had rooming houses for the temporary workers who came in the winter

to cut ice, which was stored under sawdust, from the many local saw mills, in the ice houses for shipment by

rail to cities in the Boston area. One of the companies was the Lynn Ice Company.

After the development of the home refrigerator and commercial ice plants, the traditional ice cutting industry

vanished quickly. The three ponds in Milton were gradually developed into summer vacation "cottages", or, to use the

New England term, "camps". Many of the owners of the camps by the time we moved there were from the cities near Boston

which had been the former customers of the ice companies cutting ice in Milton.

At the time we moved there, the town of Milton had a total population of about 3,500. It had a "representative town

meeting" form of government, which meant that a group of three elected "selectmen" conducted the town business

between annual town meetings of all the town residents. The town meeting voted on various issues and

authorized expenditures, providing guidance to the selectmen, who were also elected at the time of

the annual meeting. Living there was a great introduction to democracy as

practiced in the rugged individualism of New Hampshire. It was also an introduction to how incredibly

talkative the reputedly taciturn "Yankee" is at a town meeting - held in February, when cabin fever is

at its peak, and people are desperate for any human contact.

The farm itself was all that remained, about 70 acres, of some 1,000 acres formerly owned by one of the Plummer

families (Lewis Plummer) and used by them to raise and train oxen for their logging operations on the other large

properties they owned in Milton. By the time Lewis Plummer died, the farm was the residence of one of the daughters,

Agnes Plummer, the other two daughters having moved away. Agnes never married and lived at the farm, which was

by then operated as a dairy, "Plummer's Homestead Dairy".

Here's an aerial view of the farm about 1960. By the time we bought it, the annex to the barn had collapsed and

been removed, and the workshed toward the river was in ruins. The hen coop and carriage barn were still standing

and in good shape when we arrived.

This is a picture of Lewis Plummer and some of his oxen from the late 1800s. Note the huge pile of

firewood in the background.

One of the men who managed the dairy for Agnes was Louis Tibbetts. Louis wrote a wonderful personal and anectodal

history of the Village of Union. At last check, his writing is available on the web through a Google search for "Louis

Tibbetts" or "A History of Union, New Hampshire". The history is complete through 1992 with a few later updates and

is an interesting read.

Louis operated the farm until he moved to Union and ran the general store there.

Tibbetts General Store was a real country store, known for the quality of meats he sold and for the

"New York Washed Curd Tasty Cheese" he kept on the counter. Still the best cheese in our memory. Louis retired and

sold the store shortly before we arrived and the new owners maintained much of the character of the old store as long

as they could, but in a few years, it had evolved into more of a convenience store with beer, sodas, and snacks being

the bulk of the business. As the mills moved out or closed, the small villages in all the area became bedroom

communities, and

people commuted to nearby cities, Rochester, Dover, Portsmouth, for work. And did their shopping where they worked.

Louis Tibbetts never sold beer because, as he said, "I never saw the need of it.". His successors had no choice in

the matter.

There were other effects of the closing of the small mills and the loss of the small farms that supplied the

towns. One of the most important, and perhaps most damaging, was that the working men and women of the

town were gone all day, every working day. That meant that for example, selectmen were not available to

handle problems as they arose and organizations such as the fire department, run by and dependant on

volunteers began to wither and die. By the 1990s it was hard to staff the fire departments reliably.

In Union, the alarm would sound at the fire house, and after half an hour or so, with no one to respond

and silence the alarm, someone from the country store would walk across the street and shut it off.

A way of life was passing.

Sometime in the early 1960s Agnes Plummer sold the farm to Charles and Louise Barrett, who ran it as a

dairy farm into the late 1960s.

Charles was a lumberman by trade, and had operated the New England Box Company saw mill just south of the farm

until it succumbed to the declining demand for hardwood for the furniture factories in Massachusetts as those

factories

moved south to North Carolina in the late 50s and 60s. The Barretts then

sold the farm to a developer, who set about subdividing it and selling off the better land piecemeal.

We bought as much as

we could from the developer and put together 70 acres the hard way.

Fortunately, Charles and Louise had built a home nearby and for years helped us learn to farm. We started with a

dozen sheep and big plans for an orchard. We learned to hay, putting it up loose by hand in the barn with the big

grapple hooks hoisting it up to the third level to be then forked over into the lofts. We learned a great deal

and ate

well. We are still grateful for all that Charles and Louise taught us, and speak of them often as we enjoy some

favorite recipe or work in our garden. They were wonderful friends and mentors.

Our Sheep and related adventures

Looking back, it is hard to remember a reason to start raising sheep. We had planted the

first apple trees for our planned orchards, and sheep don't really get along well with

little apple trees. They eat them. So having sheep meant lots of fencing to keep them

contained and away from the trees. Probably we got the sheep because of our contining

interest in weaving and the fiber arts.

We brought a small flock of thirteen sheep from another recent "homesteader" arrival

to New Hampshire, who wanted to get rid of them. We soon found out why.

There was a Suffolk ram ("Sam")

together with twelve ewes of various, largely nondescript lineage. We brought

the lot of them home to the

farm tied in burlap feed sacks in the back of our Dodge station wagon. Jim, son of

Artie and Merce Silverman was visiting us and pressed into service as my assistant

on that trip. An experience he is not likely to forget.

Sam was a pretty good ram, as rams go. He was definitely up to his only task,

impregnating the ewes. But we discovered, after a couple of difficult lambing

seasons, that Suffolk sheep tend to have large heads, and the many of Sam's

lambs had difficult births, ending up in the house as bottle lambs. We swapped

Sam off and got a Corriedale ram and soon had much better lambing times. We also

got better educated and smarter about raising sheep.

The first year we had the sheep, we did not make any effort to manage the lambing. We just left

the ram with the ewes in the late summer and we had lambs dropping in the depth of winter

at irregular intervals. We ended up with a couple of lambs in the house on the bottle when

they were not adequately cared for by the mother or abandoned.

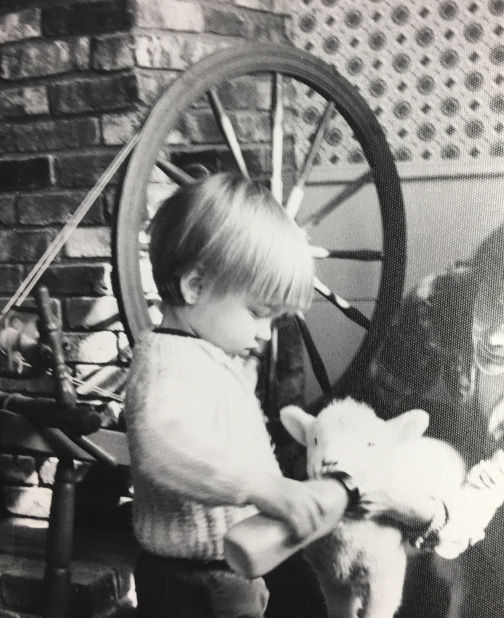

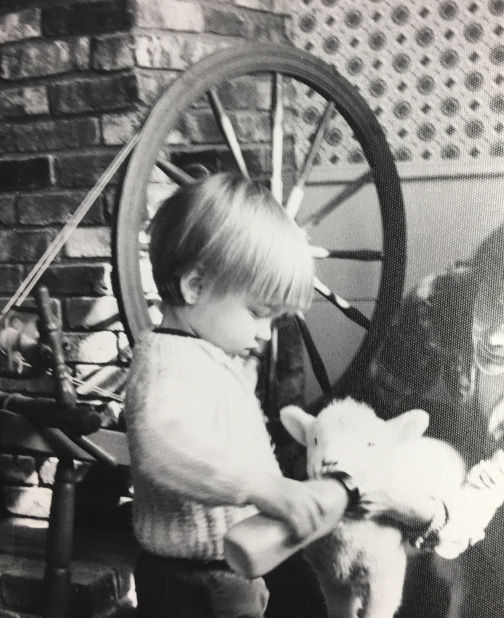

Here are some pictures of our bottle lambs through the early years.

Later, as we learned more, we were much more organized about lambing. We had raised a black

ram lamb, Fred" on the bottle, shown in the picture above, before we learned that

the black color is likely a recessive trait.

Because we had hopes of having a flock of sheep with fleece of different colors, and

kept the lamb, a second ram, to perhaps breed

some black progeny. Fred, however, even though still young, when he was put out

with the rest of the flock, became agressive, and we decided to butcher him.

Fred was delicious,

and we thereafter kept a lamb for ourselves every year, and also converted our thinking from

raising sheep for the fleece to

raising lambs for the Greek Orthodox Easter celebration. There was a sizable Greek American

community in nearby Dover and Somersworth, and a local slaughter house/butcher who catered to

their desire for small (30 pound) lambs for the traditional Easter feast. We found we could

easily sell all the lambs of that size we could produce.

So we learned to better coordinate the timing of our lambing season. We looked up the

date of the following year's Easter, allowed thirty days for the lambs to reach a weight

of about thirty pounds, then counted back 5 months, the gestation period of a lamb and

came up with a date of desirable conception. Naturally we needed the ram and the ewes

to cooperate. The ram was no problem. The ewes, however, needed a little persuasion, as

sheep do not have a regular or recurring estrus. Rather, it is the presence and activity

of the ram which induces an estrus. So we learned to keep the ram away from the flock for

several months, then "flush" the ewes with extra nutrition (more grain) and put the ram

in with the ewes. Sure enough, the ewes entered estrus more or less at the same time, and

we ended up with a lambing season that lasted 7 to 10 days, instead of a couple of

months. And we had plenty of lambs for Easter.

Of course, with sheep comes the obligation to feed them through the long New Hampshire

winters. We were delighted to find out, from Charles, that all that "grass" growing

in the fields around the farmhouse and barn was actually "hay". Timothy and clover hay.

Good for feeding sheep.

We did our first haying in the "old way". We did purchase a hay mower, a used sickle bar

mower that attached to the tractor, and an old style "dump rake" . Charles taught us

everything we needed to know about haying and

led us through the process that first year. He told us when the hay was ready to cut,

when the weather had likely stabilized for a few days, long enough to dry the hay,

and when the hay was dry enough to put into the barn. We cut the hay and tossed it about

a bit while it was drying, then loaded it with hay forks onto the wagon and then into

the barn. We backed the hay wagon into the barn and used the old overhead grapple

hooks to lift it onto the third level of the barn from where we then forked it by

hand onto the hay lofts on each side. Charles showed us how to operate the hay lift

and helped us handle all that hay. The next year, we got a "tedder", a machine to

stir and toss about the hay to hasten drying. A couple of years of haying by hand

made us really appreciate the baler, when we finally got one.

Here are some photos of the early days of making hay.

And here are a couple of shots of haying after we had the baler, which we got in the late 1970s.

A baler is something that you develop a love-hate relationship with. When it is working well it

is a wonderful, labor saving device. But when the knotters are not working and the machine

is too hot to touch in the July sun, and the thunderheads are building up to the south, well,

that is a different situation. Along with the baler, we got a new rake, a side delivery

rake which was also a tedder. It fluffed up the hay nicely, and then raked it to the side

in long windrows for the baler to gobble up and bale. All in all, however, the best equipment

purchase was the electic powered

hay conveyer, which took the bales up to the second level of the loft, sparing us from

having to lift them up to the second story by hand. Next time, the conveyer will be the first

item I purchase for haying, not the last. And the baler will be the second.

During the first few years at the farm, we continued to work at Macrame and weaving and writing more books.

For more detail on the books written on Macrame and other crafts during the early 1970s and later phamphlets

on handweaving see our Publications Page. But we were very

busy figuring out how to live on the farm - learning how to heat the place and starting to develop it as a

working farm. We planted some apple trees early on, had an enormous garden, and got those of sheep.

All these efforts were aimed at becoming relatively self-sufficient and developing a source of income for and

from the farm. And soon occupied most of our time. It is said there are only two seasons in

New Hampshire: Winter and Getting ready for Winter. That is certainly true on a farm.

The second year, and for many after, we had a large garden. Charles knew the land well

and could tell us where the best land for

gardening was located. The first couple of years, he plowed and harrowed the garden for us

until we got the equipment needed to do it ourselves.

Our good teaching from Charles and Louise and our willingness to work very hard

more than made up for our lack of knowledge and experience.

The garden produced well and we learned how to "put food by" for the winter. Some things we canned

and some we froze, but we harvested and stored enough for the entire year. After we added chickens

to the farm, we also had fresh eggs as well as fryers, broilers, and stewing chickens. Later, we

raised a hog every year and put up salt pork and lard as well as the pork from that.

The pictures below show the harvest from 1972. There are green beans and wax beans and pickles

and saurkraut in jars on the shelves in the root cellar, and bins with potatoes and winter squashes.

And tomatoes.

Lots of tomatoes. We made juice, sauce, soup, ketchup, and green tomato relish. The peas and

corn we froze, but we also made corn relish and various pickles with other vegetables from the

garden. After several years, we had a Thanksgiving with a large roasting chicken and all the food

except coffee, salt, spices, and flour from our garden.

Here is a photo of the farm as it looked around 1973/74. The 1963 Toyota Land Cruiser, which had traveled from

Philadelphia to New Orleans to New Hampshire is in the driveway, and it has been joined by a 1972 Land Cruiser

station wagon. The Land Cruiser staton wagon replaced a 1964 Dodge station wagon we had bought in New Orleans,

largely for the air conditioning.

We kept the Land Cruiser station wagon until 1976 when we traded it in on a Chevy 4WD pick up truck for the farm.

It is the only time we have traded in a car for twice what we paid for it, a fact that attests to the rapid

rise in prices for those vehicles during those years.

Spring, summer and fall were busy times,

and winter was almost welcome as a time to slow down and catch up on other things. But mostly

it was time spent keeping the wood stoves full and the ice off the roof(s). We burned about 15

cords of wood each year during most of the time we lived there, sometimes more. Firewood

may have been our most important crop.

The first years we spent trying to figure out how to best stay warm in the winter. We did

a lot of remodeling and insulating, and added two fireplaces. But the most important thing

we did was to experiment with woodstoves that controlled the burning to maximize heat

production. We first added a massive enameled cast iron wood stove to the kitchen to use

as cookstove as well as a source of heat. This experiment was a failure, as the

firebox was too small and there was not good draft control. This was followed by an

Ashley Stove, a basic steel barrel stove with a thermostat-controled damper. The

device was really simple; a bi-metallic coil that was in the air flow to the air intake

of the stove and

had one end attached to a small chain that raised or lowered a flap valve on air intake.

There was a damper in the stove pipe also, but mostly the combustion was controlled by this

arrangement. It did not take long to figure out the proper setting to get a long burn

and maximal heat production. The stove was prodigiously ugly, but after the first few

cold weeks of winter, we thought it beautiful.

The Ashley stove was soon replaced with a large Jotul stove, a cast-iron Swedish stove

with a tight sealing door and a draft control consisting of a simple rotating valve. The

Jotul was wonderful and would burn 12 hours on a load of wood most of the time. When the

temperatures fell to 20 degrees below zero (or lower) we did get up at night to reload

the stove, but most of the time it lasted 12 hours at night and 6 to 8 hours in the daytime.

It worked so well, we got another for the living room and the two together heated the

house very well. For a couple of years, they were our only heat, but for the most part,

supplemented the oil-fired furnace in the main house.

Later, when we moved the yarnshop to the loft, we added a small Jotul box stove there and

it worked as well as the big one in that space. Years on, when we moved the yarn store

to the barn, we added a coal stove to that space.

We spent a lot of time and work heating the farm. But, over time, we got better and

more efficient at that. In the early 1990s we replaced the old hot air furnace with

an oil fired hotwater system with baseboard heat and at that time we moved the Jotul

from the living room to my workshop in the barn, keeping the Jotul in the kitchen, the

Jotul in the loft, the Ashley in the wood shop, and the coal stove in the yarnshop.

By that time, Gene was harvesting just over 15 cords of wood a year from the woodlot,

which was self-sustaining. He cut the wood each fall, splitting it and stacking it in

the woods to dry for a year. The next fall, we would move the split wood over the creek

to the barnyard to dry another year, and move the prior year's stack from the barn

yard to the wood room, adjacent to the kitchen. The wood room held just over 15 cords

of split wood. We burned a mix of red oak, maple, and ash, with some poplar and pine,

the latter to use on days when we needed a quick fire to take the chill off but not

a day long fire.

The farm lay on land that had been glaciated in the last ice age. The glaciers

had moved across the land, taking the tops off the hills and small mountains, and

grinding the rock into sand and gravel that was deposited on the south side of

the remaining hills as the glaciers retreated. Our farm had rich and extensive

deposits of sand and gravel on both sides of the small river (creek, really) that

bisected the farm. Much of the land had been excavated for gravel "borrow pits"

in the 1960s during the construction of the part of state Route 16, which

had by-passed the villages of Union, Sanbornville, and Wakefield, as it

hurried the tourists along to the White Mountains, lakes, and ski areas to the

north.

In the 1970s we sold some sand and gravel to a contractor working on more

by-passes, this time by-passing Milton. The contractor re-opened the pits and

extracted a couple of acres worth of material. The money from the sale of the

minerals was most welcome revenue to the farm at that time.

Later in the 1970s and early 1980s a local contractor approached us about

re-opening the pits and buying material from us. He wanted to build a bridge

across the river instead of fording it, as had been done before, and offered

to build a bridge and roads to access the pits in exchage for a discounted

price on the material and an exclusive contract. We agreed, and he built the

bridge and roads as promised. The accounting he kept on the amount of material

being removed, however, was a bit sketchy, but before we needed to confront

him about the discrepancies, his business went under, and we were left with

a fine bridge and roads, and no obligation to sell any more material.

Later, the abandoned sand pits grew wonderful crops of blackberries along

the edges, and made for fun jeep riding.

In short order the sheep led to selling yarn. First we traded fleece for yarn with the Bartlett Mill

in Maine and sold yarn from our kitchen. Then we expanded into the second level over the "ell"

connecting to the barn. And with more space, we added more types of yarn. The Bartlett yarn

was a "woolen" spun yarn, softer and loftier than a "worsted" spun yarn. But the worsrted

yarns were stronger and longer lasting, so we added some excellent weaving yarn from

Harrisville Designs company in New Hampshire. We also sold their looms and later, added

the line of looms and equipment from Schacht Spindle Company. The business grew and we

advertised a little.

Then on afternoon, a gentleman named Bill Spratt walked into the loft where the shop was

located and visited for a while getting to know us and the business. It turned out he

was managing the development of a new yarn company, Elite Yarns, which was

and offshoot of the Worley Worsted Mill in Lowell, Massachusetts. Worley had old

weaving equipment capable of spinning fancy yarns and of handling mohair. Although

the company made most of its revenue from making cotton mop cord, the owner wanted to

use that specialized equipment for a new line of yarn. He brought Bill, who had worked

for Berrocco yarns for years, in to design and develop the yarn and create a business around

it. The yarns were spun mohair and mohair boucle and brushed mohair in current colors and

ombre yarns. Bill needed a business to handle his growing mail order business and asked

us if we would be willing and able to handle it for him. We agreed and, on a handshake,

he arranged to ship us a large inventory of all the colors and blends in the line as well

as all the sample cards, stationery, and other supplies we would need. It was a

tremendous boost for our shop, giving us an instant mail order business and also a

superb inventory on hand in the shop for our local customers.

Later, after several years of working with Elite and Bill, we asked him why he had

picked us to partner with. He replied simply that he needed someone he could trust, and

based on our advertising and on meeting us, he trusted us. The relationship lasted for

perhaps five or more years, until Bill had grown the business in Lowell and could hire

enough staff there to hande the mail order for him. He even had us do a small pamphlet

of knitting patterns for Elite. The pictures for the pamphlet were taken at a mohair

"ranch" in Texas. Texas was, at that time, the largest mohair producer in the world.

A few years after that, Bill and Elite parted company when the owner's wife wanted to

take over the business. It became Elite Specialty Yarns and continues to this day, but not

in Lowell. Worley closed down, also, and the yarn is not made there anymore. We lost track

of Bill, but will be always grateful to him for a great gift to us and for showing

us around the mill and giving us insight into the yarn and textile business.

In a few years after partnering with Elite, we expanded the shop again. In the late

1970s, we renovated the barn to add a large commercial cooler for the apples and at the

same time, converted the south - facing side of the barn into retail space. That side

had been cattle tie-ups and stalls in the dairy days. We kept the north side for the

sheep. By that time we had also added a dairy goat and later we had a mohair goat, also in

that space.

<.p>

The remodeled south side of the barn was about 1200 square feet and we turned it into a

full-fledged yarn shop, specializing in weaving supplies and exotic yarns. Ellen ran the

yarn shop, gave knitting, spinning, and weaving lessons, watched the apple stand, and raised

the children. We were fortunate to have a series of local young ladies to help with the children.

Stacey MacDougal, Mary Pomery, and Kathy Richards were outstanding, and you will often see

them in pictures of the children and of the farm.

The left hand picture below shows the yarn shop in the early days, in the loft.

The picture on the right shows Gene and Tom weaving on small table looms we made at

the farm and sold in the shop.

The yarn shop was very successful and we both worked at it, teaching classes as well as

selling yarn. Ellen grew a large and loyal customer base. And it certainly was much less

capital and labor-intensive than farming.

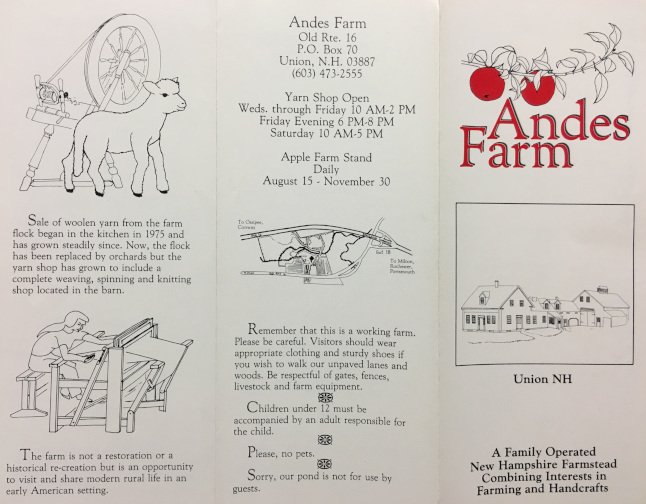

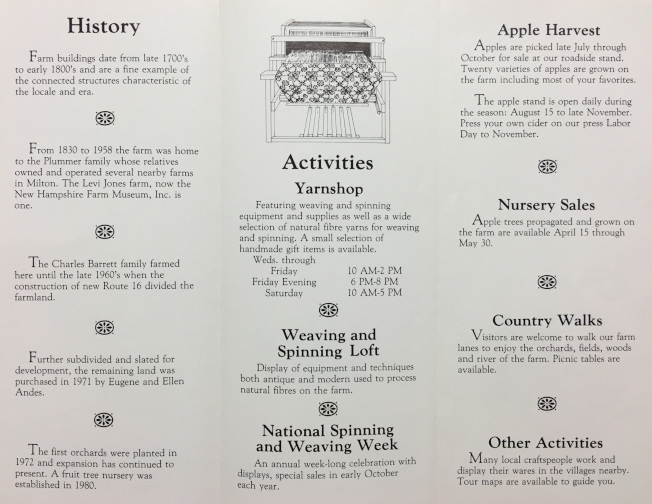

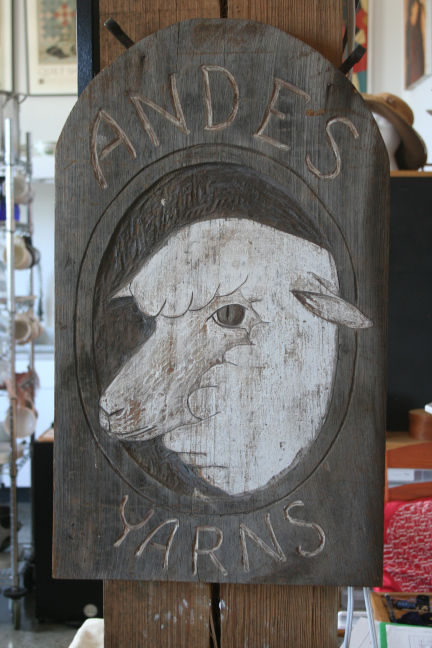

Here are some pictures of the advertising tri-fold brochure for the farm and the

yarn shop, and a bookmark from the shop. And a picture of the sign that

hung above the entrance to the "first" shop, on the second floor of the "ell",

above the woodshed and the workshops. The sign moved to the "second" shop in

the barn, then with us to our various home through the following decades. The

sign in the picture below is hanging in the living room of our current

apartment.

When we went overseas in 1986, we closed the yarn shop and got rid of most of the inventory, although

Ellen kept two floor looms, a table loom, a spinning wheel, and plenty of yarn. We hired a

young couple to live at the farm and manage it while we were away, with the intent of

selling it to them on our return. More later.

After first year we were at the farm, we planted about two acres of apple trees.

This first planting included

many different varieties - the popular varieties -McIntosh, of course, and red delicious,

golden delicious, Jonathan, and Rome - but also some older types - Northern Spy, Rhode Island

Greening, Yellow Transparent, Milton - and some newer one - Paula Red, Macoun. The trees were

"semi-dwarf" trees, the parent stock (scion) grafted to a wild-type root stock that would

limit growth and keep the trees, with proper management, small enough to manage without

ladders. This first planting did well, and began to produce small crops in about 4 years.

At about that time, we planted an additional five acres, about 2500 trees. This expansion

was to be a variety of apple called Milton, similar to a MacIndosh, and chosen more for the

name than the quality of the apple. After growing the trees for three years, the first

fruit showed that they were not the variety they were supposed to be. The nursery from which

I had purchased the trees had shipped another variety. So they shipped replacement trees

and we replanted. This time, the variety was a Spur MacIntosh. After the third growing

season, when the trees had formed the lower whorl of branches that would carry most of the fruit,

we had a severe winter with lots of snow. The snow accumulated to 2 to 3 feet high in the

new orchard and then, after a bit of freezing rain followed by a deep freeze, forming a

thick layer of ice on top of the snow. A February thaw followed, which melted the snow below

the ice causing the ice to drop about a foot or more, shearing off the main lower

scaffold branches of the trees. Which meant the process of growing and training them had

to start again, for the second time.

Despite all the setbacks, we continued to expand the orchard, planting another 7 acres in the

1980s using a different rootstock and an even denser planting of 800 trees to the acre.

We also began a small nursery and Gene learned how to propagate apple trees by budding.

Budding is a form of grafting in which just the axillary bud, at the base of a leaf, is

used for the donor stock. It is thinly sliced off the donor branch and inserted into a

superficial cut in the recipient rootstock. It is faster and easier than traditional

grafting, and produces a fine result. The budding is done in late summer, after the buds

have formed. The rootstock, with the bud in place, is grown through the fall and winter

and in the spring, once the bud sprouts and the desired donor stock is growing well, the

rootstock above the graft site is romoved. Although Gene grew the nursery stock for

replacement trees for the orchards, we also sold them.

In 1985 we got an opportunity to work abroad, in Saudi Arabia, and decided to take advantage

of the chance to travel and work for a guaranteed income. We hired a couple to run the farm in

our absence, which was to be at least two years, and ended up a bit more. We paid the couple

a salary and provided a budget to cover most of the costs of continuing the running of

the orchards. We closed the yarn shop, put most of our household goods in storage, and set

off on an adventure. That adventure is chronicled in the Saudi Arabia Page. While there, we lived in a large city (Riyadh) in a

desert, where it was warm and sunny pretty much all the year. It also afforded great

opportunity for travel.

When we returned, we decided to conclude the farming operation for many reasons.

Mostly, the reasons were economic. Although we had been producing enough income from the

orchards to cover running costs, there was not enough to cover the costs of capital -

the costs of replacing equipment and the costs of paying the mortgage and taxes.

Equipment that had cost $2,000 in 1971 was costing $20,000 to $30,000 and more by 1987.

Taxes were also increasing, as in New Hampshire,

property tax is the only source of revenue for local governments, and the public schools were,

at that time, almost entirely funded by each township. We realized that, although it was a

good life, we were spending money to keep it going, money that would be needed for the

children's' college education. And although we enjoyed the farming way of life,

our kids did not. Plus, after two years of sunshine, we were tired of the cold and the long,

dark winter. It was also getting harder as we got older to maintain the property

and to cut the wood for each winter. Two years in the sun of the "desert kingdom" and

living in an urban metropolis

had given us a glimpse of another way of life.

When we fist returned home, we spent a lot of time and money remodeling the

farmhouse. We replaced windows, adding larger windows to the south facing side, and

re-sided the house and the ell in cedar. At this time, we also replaced the heating

system, and the roof, and remodeled the interior. We had custom interior doors made

to match the originals, built custom kitchen cabinets and replaced the kitchen counter

tops with tile. We finally had the house the way we wanted it. Cozy warm in winter, and

in good enough shape to keep maintenance low. Gene went back to school to get a business degree

(MBA) and Ellen worked full time as a high school librarian. Gene had fun with antique jeeps

and continued with his ship modeling, which he had resumed while overseas. Ellen

continued her fiber arts and the children went back to school.

But things were not the same. We found the cold and dark winters over-long. The kids

found the local public schools were not up to the standards of the American School in Riyadh.

We tried some private and alternative schools for the kids, but in the end, we no longer

fit in our former home.

Then began a serious job search, and in 1994, we left for Ardmore, Oklahoma, to live and work in a

small city and try the urban life in a warmer climate. We could not sell the farm until 1999

and then sold it at a

great loss. In the years since we first moved there, it seemed the romance of

living the farming life had diminished.

It certainly had for us. The lessons we learned there, and the memories made, however, are

without price.

When we first bought the farm, we bought it together with a dear friend, Betty, from New Orleans. After about

half a year, however, it became just to difficult to make decisions and plan for expenditures collaboratively so

we divided things up. Betty took the carriage barn, had it moved to a parcel next to the farmhouse which was

then deeded to her, and she remodeled it into a lovely second home. We were then left to develop the bulk of the

farmland as we wished.

Dale Schwichtenbeerg was a student at Hamline University and working in fiber arts.

He wanted to learn Macrame, and in a conversation with Mike Price, our sculptor

friend from New Orleans who had taking a teaching position at Hamline in 1970,Mike

suggested he contact us to arrange a study residence with us

in New Hampshire. Dale stayed with us for a while, went back and finished college

and later returned to live with

us for several years. In the interim, he had worked for a time as a printing assistant to

Mauricio Lasansky, the renowned print maker, who had founded and chaired the Printmaking

department at University of Iowa. Dale wanted to establish a fine art printmaking studio

in New Hampshire and set up a printing press in our garage for a time, but

did not find enough business in rural New Hampshire to make a living. While he lived with

us he helped out on the farm and we hung his many Lasanksky prints on our walls. He

had obtained "artist proofs" of each of the prints he had assisted with printing the edition,

so there was an impressive collection. He also introduced us to the work of Leonardo

Lasansky, Mauricio's son, who was professor in the Art Department at Hamline University.

But in time, with no printing business developing, Dale moved on, press, prints, and all.

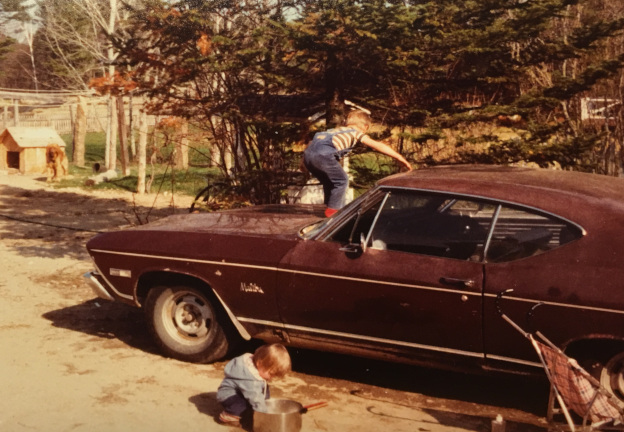

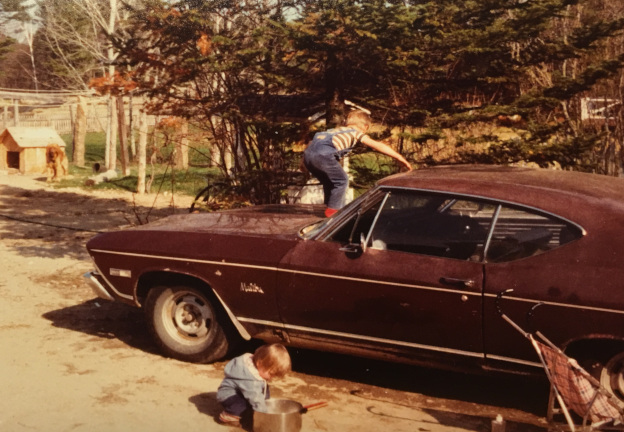

Here are some pictures of Dale over those several years. You can see how Tom has grown

when you compare the pictures. And the addition of Robert assisting Tom in

washing Dale's car. Fortunately, Dale was a very patient man.

Dale was not the only student we had stay with us. Edith Andersen, from Copenhagen,

also stayed with us several months to learn some of our Macrame techniques, and

we learned a number

of her Danish knitting techniques. Here's a shot of Edith at the farm.

Below the picture of Edith, there is a collection of pictures of various friends

and neighbors, often pictures taken at birthday parties or holiday occasions.

The pictures include friends Holly, Hilde, Rhonda ("Woodsie"), Anna and Inge,

a colleague, Sue, and neighbors

Glenn and Lorraine, Charles and Louise, and visiting family. The last pictures

show our brother-in-law, Marc, with Ellen and a load of firewood, and

a photos of

Ellen with her mother, Clara, and her aunt Edna and the kids, also with

firewood in the background.

Some time after our return from Saudi Arabia, while in New Hampshire, Gene met and struck

up a conversation with a commercial

airline pilot for American Airlines, who was soon to test out with the FAA in a Vampire jet

to certify to fly it. He invited us to the

test trial, and we had a wonderful time looking over this interesting early military jet

and watching the test flight. It was a two-seater, and the FAA guy had to go along for the

trial flight, so none of us got to fly, but that was fine. We also met the owner of the

plane and learned from him a bit about the world of those folks who collect old "war birds".

The Vampire was made by DeHavilland in the late 40s and 50s

and was one of the first operational military jet aircraft. It was pretty primitive

by today's standards, with an engine that had little power, resulting in a very slow, smooth

taxi and take off. The air frame also had wooden parts, especially the nose. The plane had

twin tail booms with the engine in the center of the main wing.

The Vampire was used by many countries,

and one of those countries was Saudi Arabia. The Vampire was one of the first

aircraft used by the Royal Saudi Air Force, and is enshrined by being mounted in one of

the "sculptures" in the "roundabouts" in Jeddah.

When we returned from Saudi Arabia, we closed down the farming operation and

had more time to enjoy simply living at the farm. We renovated the house for the third

or fourth time and developed the wood lot so we could supplement the heating

systems with wood stoves. We got a jeep to use around the farm, especially in the

wood lot, where a full size pickup was too big to thread through the forest. And

that started us on a long love affair with jeeps. To see more about that, just

go here.